Munich Startup: Who are you and what does Manaomea do?

Tine Arlt, founder of Manaomea: We are Manaomea, a social impact startup. Manaomea stands for the best possible recycling of textiles. With our innovative technology from the aerospace industry, we eliminate textile waste by transforming it into a unique, characterful and strong material.

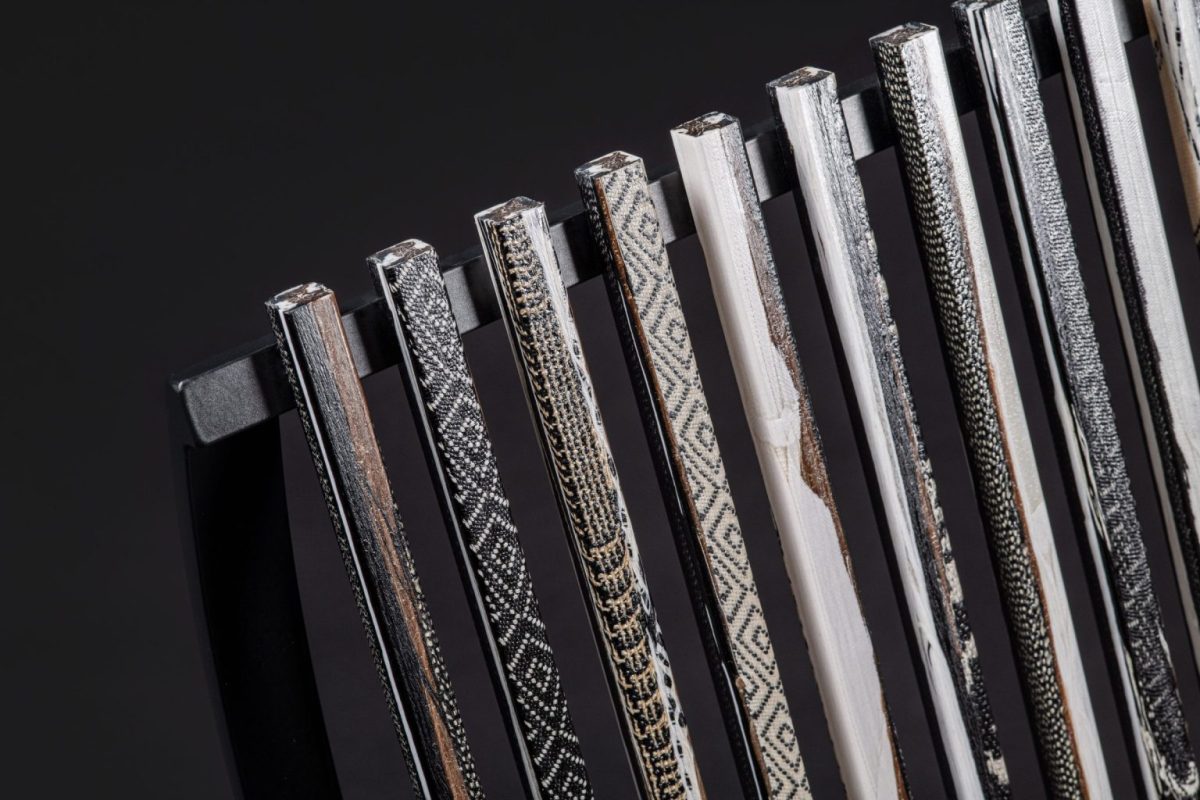

Our Manaomea material is unique to every millimeter, super authentic and naturally circular. With a wide range of applications in the most beautiful rod-shaped designs, it can be used like (tropical) wood and plastic both indoors and outdoors, while the trees remain standing. Today, we use it to make very special pens – the Betterpens – and in the next step, unique furniture and interior design such as innovative skirting boards, wall panels, jewelry and accessories. Our material can be used in endless circles. From pen body to chair to floor, over and over again, without any shredding.

From 2025, it will finally also be manufactured at the textile waste mountains in the global South. After all, it has been our long-standing goal to work where all the textile waste, which also comes from all of us here, is produced. And to bring about real change there with our technology and socially fair jobs.

Space-Tech for textile waste

Munich Startup: What tech features do you use to apply cradle-to-cradle principles?

Tine Arlt: We use our technology from the aerospace industry to transform any type of textile waste together with our bio-resin into our unique Manaomea material. We produce rods of different geometries – always rods. This is the trick that allows us to recycle and re-produce every rod and every product made from it without shredding it. In this way, small rods such as pencil casings can be turned into larger rods that are used in interiors, furniture and other applications.

Munich Startup: How do you incorporate the circular economy into your business model?

Tine Arlt: For us, circularity starts with the design idea. Right from the start, we used an incredible amount of creativity and patience to design our material in such a way that it can be guided in a circle without being destroyed. This is how the rod-shaped design came about. Each of our products is designed according to minimal and circular design principles so that it can be completely disassembled and recycled.

Circular from the material to all joining techniques

We reduce to the essentials. No unnecessary frills. For example, our Betterpens are made only from textile waste and bio-resin, with interchangeable refills, some with stainless steel parts. That’s all they need. And each pen body can be returned to our material cycle to become a rod for a piece of furniture, for example. The pen sleeve remains completely intact. A small pen becomes a larger pen, an even larger pen, an even larger pen – endlessly. And we simply love our Betterpens. They are true impact wonders. The first social circular upcycling pen made from waste. It can be kept in its cycle forever and also serves a social purpose – fair jobs and fair wages directly in the textile waste mountains of this world.

Following the success of the Betterpens, we are continuing with larger bars to create new exciting products such as furniture and interior designs. We want to increase our reach and impact through collaborations with great furniture brands and other partners.

Translating high-tech into smart, cost-effective systems

Munich Startup: What can other startups learn from you?

Tine Arlt: Other startups can learn from us how to translate super-innovative high-tech into smart, small, decentralized and cost-effective systems that can have a direct impact at the source of the problem. Technology transfer to the global South instead of huge plants in the global North. In this way, we not only create sustainable solutions locally, but also empower local communities and transform them into innovative centers.

We show that it is possible to see real waste as a valuable resource and transform it into beautiful, unique products. We love materials and could lose ourselves in the unique haptics and small details that are created from textile remnants. We love our planet just as much. It’s so beautiful here! That’s why it’s so important to us to achieve a holistic impact. From the material itself, socially on site and in terms of the circular economy. We are delighted when our material is used in many industries.

Munich Startup: What are your current challenges?

Tine Arlt: Growth and visibility. We are in the middle of a financing round in order to delight the next markets and, above all, end customers with our material. To do this, we need visibility, great partners and a significantly larger team. Because next year we will also be launching our first partnership for our first location in India. We are currently still in the process of selecting suitable partners.

Challenges: Finding capital and scaling

And we are working on scaling up our production and diligently developing new inspiring products made from Manaomea material. This also involves optimizing our processes so that we can process larger quantities of textile waste.

Munich Startup: Where do you see yourselves in five years?

Tine Arlt: Let me think big here: Manaomea is a leading impact company that enchants the world with its unique material and makes a significant contribution to reducing the world’s mountains of textile waste. Our material is THE trend material and Manaomea is a global impact brand!

Together with great partners, we have at least six different locations with socially fair production worldwide – wherever there are mountains of textile waste. But especially in countries that are severely affected by our overconsumption. Through our production sites, we feed at least 15 families locally and empower many women in particular. Each production facility saves 4,600 tons of CO2 equivalent per year and upcycles 200 tons of textile waste.

Our unique material replaces (tropical) wood and plastic in many areas and has become indispensable, particularly in interior design and furniture construction. But Manaomea material can also be found in jewelry, brushes and other accessories. They are all favorites. And we have established a global take-back system with major furniture stores, for example, so that the circular economy can really be put into practice. We particularly love our collaborations with fantastic brands such as Ikea and Hermès, with well-known designers and famous construction projects. They showcase the diversity and beauty of our material and prominently carry the all-important social impact message to the world. Together, we transform textile waste into beauty.