Munich Startup: Who are you and what do you do? Please introduce yourselves!

Caroline Legler: We are Nebumind, founded by Franz (38) and me, Caroline (32). Franz and I met during our previous jobs at Airbus, where Franz was working in central research and I was in innovation. Over two years, we successfully built a spin-off for Airbus that was specialized in sensor technology before we left corporate life and became self employed. Of course we can now put our knowledge about production lines, component quality and data processing to good use.

Munich Startup: What problem does your startup solve?

Caroline Legler: To monitor the quality of components during manufacturing, such as airplane doors, an increasing number of sensors are used these days. The sensors, however, only help monitor the known weak points. Components still often have defects at the end of manufacturing that can’t be explained. With today’s conventional methods, it’s usually too expensive and time consuming to find the cause of such defects. Instead, the defective product is thrown away or repaired.

And even if you know exactly what causes a defect, machines in the production lines aren’t adjusted immediately because it’s uncertain what side effects that might have on manufacturing. As a result, production lines often accept “minor inefficiencies” or have to conduct elaborate tests before making modifications.

Nebumind helps manufacturers reduce waste and production costs

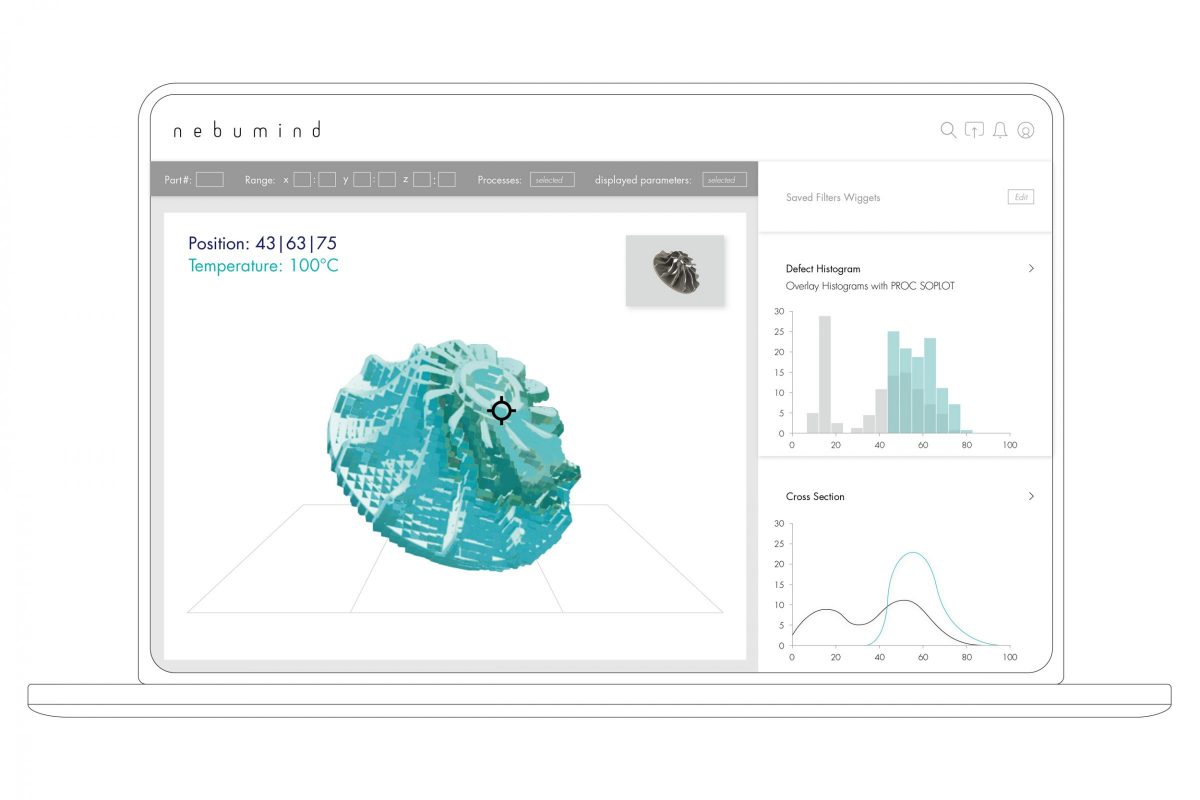

Nebumind is developing software for manufacturers that can monitor the quality of components along the entire production line. The software does so by collecting all of the production data it can from the machines and sensors during production of the component and then using that data to construct a “digital component twin” that the operator can look at on a laptop. They can see what production information is available for a specific section of the component (x,y,z) at any time. That means questions like “Why do I have a defect on the upper right section of every fifth component?” or “If I increase the speed of the machine, will that impact the quality of my component?” can quickly be answered. As a result, Nebumind helps manufacturers reduce waste and production costs.

Munich Startup: But that’s nothing out of the box!

Caroline Legler: That might seem true at first glance: An increasing number of software solutions are being marketed that collect and analyze manufacturing data. However, the solutions concentrate on efficient logistics for manufacturing or on high utilization rates for machines. We’ve yet to find software that concentrates on the quality of manufactured components and can monitor it along the entire production chain, regardless of which machine or production processes is concerned. That’s exactly where we come in with our software and manufacturing expertise.

Munich Startup: Was there a point when you nearly failed?

Caroline Legler: We originally wanted to found Nebumind as a trio, but our third co-founder decided to take a different path before the founding. Because he was to be mainly responsible for our software development, that was quite a blow to take. As is generally known, good software developers are hard to find. Fortunately, we were able to find the perfect successor from our previous network who now does an excellent job supporting us.

“We absolutely believe in our product and definitely want to put it on the market!”

Either way, we can say that even when it wasn’t clear how we would keep going, we knew we would keep going. We absolutely believe in our product and definitely want to put it on the market!

Munich Startup: How is business going?

Caroline Legler: In times like these, we can consider ourselves lucky – despite corona, we’ve been able to continue working on our pilot projects without any real restrictions. We’re particularly active in the field of space flight component manufacturing right now. Not least due to the high quality requirements for satellites and rockets, we’ve been getting very positive feedback in the field. We’re also in negotiations with manufacturers in the aviation, automotive and medical technology industries. In the field of aviation alone, our software is relevant for approximately 70,000 machines, so we have plenty to do!

Munich Startup: What do you think about Munich as a startup location?

Caroline Legler: Munich might not be the most affordable city for young startups, but has made very positive developments in recent years. Bavaria offers a host of support programs, new networks are emerging in and near Munich and investors are paying more and more attention to Munich. For us, the proximity to industry and research institutions (such as Fraunhofer Gesellschaft or the German Aerospace Center) is of particular importance, as are the good universities here in Munich, where we are always on the lookout for new employees.

Munich Startup: Coworking or your own office?

Caroline Legler: After setting up our office in the Motel One Lounge for the first six months and spending the last few in coworking spaces, we’re excited to have our own office that we can set up ourselves and equip with all kinds of IT gadgets.