Munich Startup: What does Leverage Robotics do? What problem do you solve?

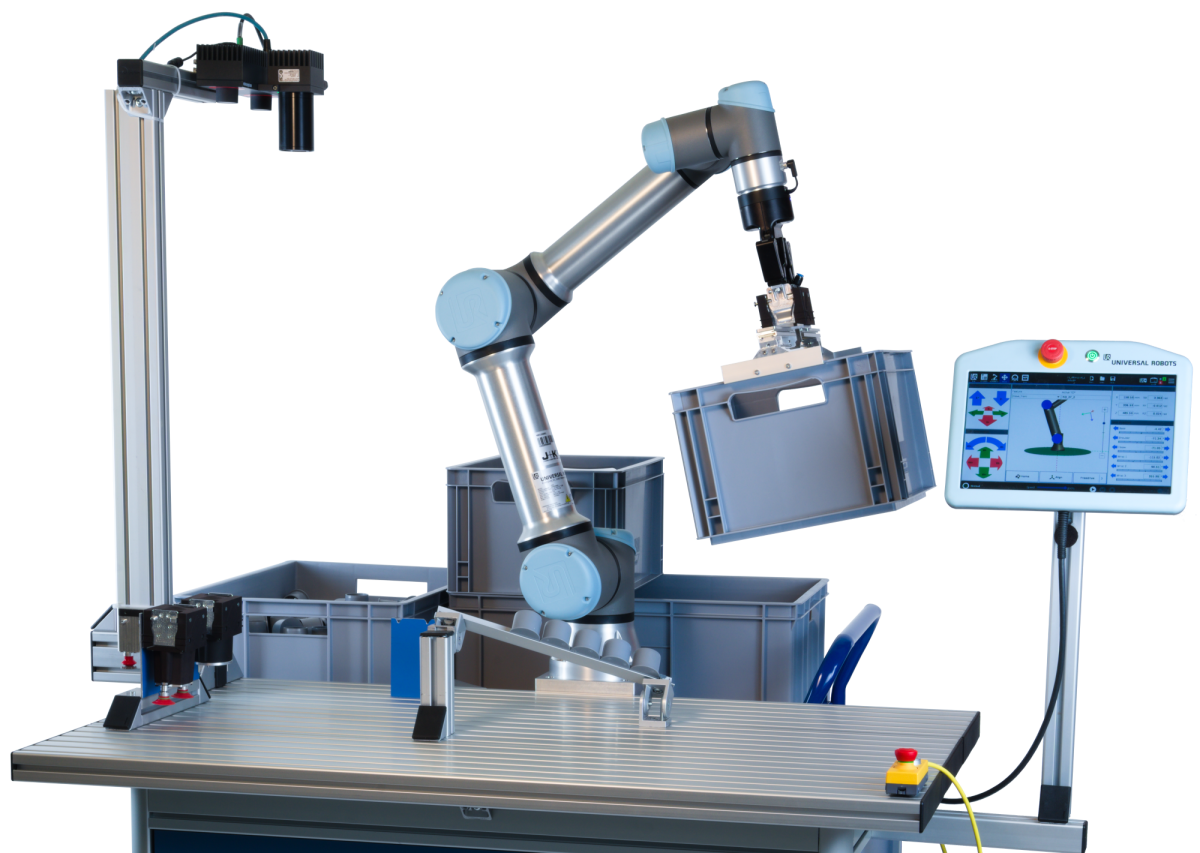

Roman Weitschat, Leverage Robotics: We at Leverage Robotics are a spin-off of the German Aerospace Center (DLR) and want to make the production of the future more flexible and efficient with the help of lightweight robots. For this we develop highly flexible and intelligent plug-and-produce robot cells for fast set-up times in multitasking applications.

With our innovative robotic tool technology, complex and diverse tasks in the field of logistics, assembly, quality and especially machine loading as well as start-of-line applications can be efficiently realised. Each of these tools has software modules, so-called robot capabilities, which enable intuitive robot programming even for non-experts. This enables regional production and prevents outsourcing of production with long delivery routes.

Munich Startup: But that’s nothing out of the box!

Roman Weitschat: Yes and no. Conventional robot systems are not very flexible and often have long set-up times in order to be able to process other products or automate smaller series. Newer robot stations rely on tool change systems that are exclusively active. This means that one gripper has to be completely replaced by another gripper and thus electricity or pneumatics always have to be fed through. Furthermore, additional connections to the control box and in the overall system are necessary. The set-up times are therefore considerably higher than with our tooling system. Our tools are passive. That means they are purely mechanical and are operated by a conventional robot 2-finger gripper.

What robots can do thanks to Leverage Robotics is unique so far

Similar to the way a craftsman squeezes his pliers, we transform this movement in our “ToolCubes” and thus introduce magnetism or generate negative pressure. In this way, we can also realise magnetic or suction-gripping tasks purely mechanically. This is unique on the market. With this technology, we can convert robot stations in the blink of an eye and realise complex robot applications much more easily and intuitively.

Munich Startup: What is your founding story?

Roman Weitschat: As a research team in the area of “Factory of the Future” at the German Aerospace Centre, we have spent many years researching flexible, self-converting and intelligent robot stations and have also worked with industrial partners in this regard. In the process, we noticed the need for high flexibility, which was primarily limited by robot tooling. And for this we came up with passive tooling, wrote an EXIST research transfer application and developed the technology. EXIST was then used to initiate the founding of a company and now we are operating independently as a company with a seed investment.

Munich Startup: What have been your biggest challenges so far?

Roman Weitschat: The biggest challenge so far has of course been a solid technical implementation, which I think we have solved very well. And the possibility of being able to act as a company. Here, the search for investors was in the foreground. Because they are simply necessary to be able to further develop such cost-intensive (robot) technologies and add new ones.

Goal: Being more competitive with automated production

Munich Startup: Where would you like to be in one year, where in five years?

Roman Weitschat: In the short term, our goal is to expand the distribution network and to get many of our products into industrial production.

In the long term, we are working to make the manufacture of products competitive in Europe through automation, to avoid long delivery routes and to be able to produce regionally economically.

Munich Startup: How have you experienced Munich as a startup location so far?

Roman Weitschat: Munich is a very good environment for startups. There are many events, coaching sessions and other startups with whom we can exchange ideas. But finding staff is very difficult. This is because many large corporations like Google, Apple and Co. are based here, and they offer very attractive jobs. So it’s very difficult for startups to attract good people.

Munich Startup: Quick exit or staying power?

Roman Weitschat: It depends on the offer. All joking aside, we are working fundamentally to build a solid company and grow it in a healthy way. That is what we have always set out to do. But integration into a strategic partner company is also conceivable.